Ib m has installed a large number of penn separator systems which offer a variety of continuous blowdown heat recovery systems designed to recover 90 95 of heat that is normally lost.

Waste heat recovery system in boiler plant.

By capturing exiting heat a waste heat recovery system effectively helps minimize long term steam plant energy costs.

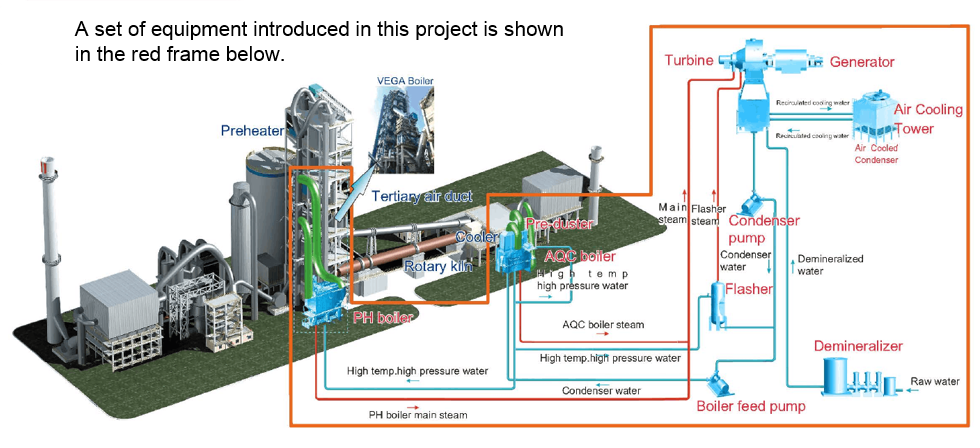

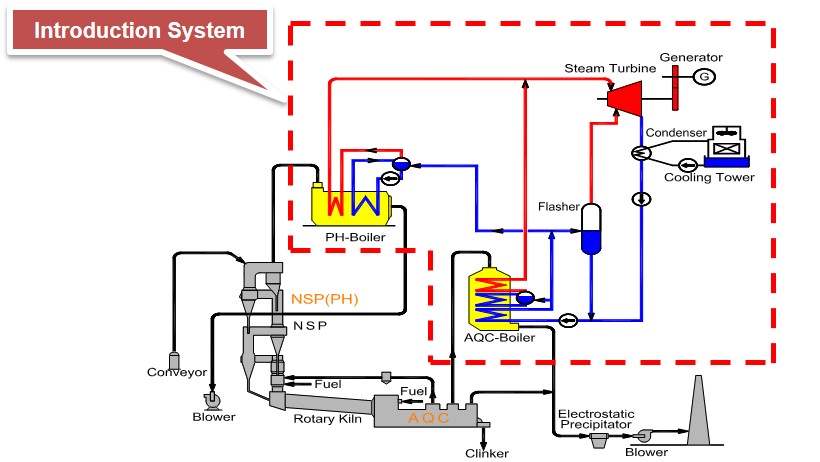

In addition to the plan of reducing of energy consumption in cement production process the recovery waste heats can.

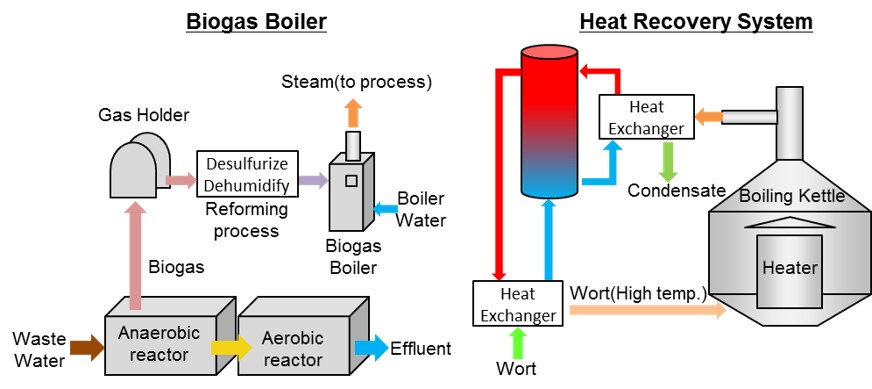

A waste heat recovery unit whru is an energy recovery heat exchanger that transfers heat from process outputs at high temperature to another part of the process for some purpose usually increased efficiency.

876 million us company headquartered in pune india.

The plant incorporated several improvements over the huntorf one including a waste heat recovery system that reduces fuel usage by about 25.

Basic concept or summary f 24 u exhaust gas heat which is discarded from various plants into the atmosphere at 250 c 350 c is recovered by a boiler to generate electricity in a steam turbine.

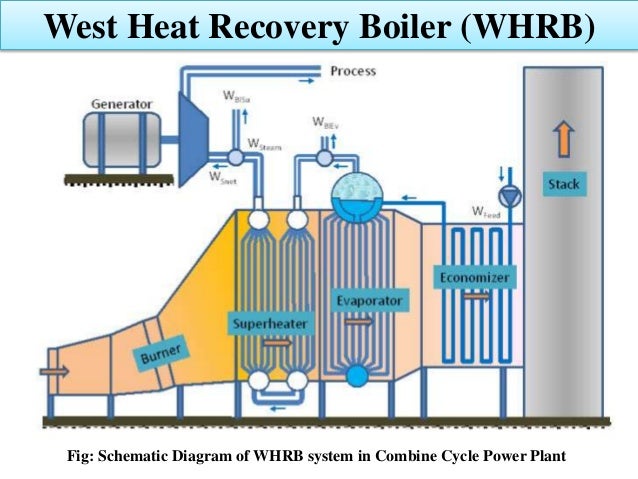

The impact of adding an economizer to the evaporator previously analyzed in fig.

The waste heat available in the exhaust gases can be recovered and used for drying the moisture in the raw material and coal or for generating power.

The steam flow from a heat recovery boiler can usually be increased by the addition of an economizer to preheat the feedwater before it enters the evaporator.

Recovery of waste heat can result in low process cost reduction in utilities consumption.

Waste heat recovery system.

Waste heat recovery power plant kawasaki heavy industries ltd.

It supports pressures from 45 to 74 bars.

3 2 the gas temperature leaving the system is reduced substantially and the steam flow is increased approximately 75.

U power generation is possible without additional fuel contributing to factory energy.

Remaining waste heat is converted into electricity.

Further using waste heat recovery boilers steam can be generated which will drive the steam turbine generator to produce electric power.

Waste heat recovery has direct effect on the efficiency of the whole process and system.

There are several other indirect benefits of waste heat recovery such as reduction in fuel consumption etc.

Thyssenkrupp will engineer and procure the turbine generator package and bop balance of plant packages of the power plant and will carry out system integration on mechanical electrical and instrumentation.

A waste heat recovery system compris ing both steam and power turbines and combined with utilising scavenge air energy for exhaust boiler feed water heating.

Air pre heater to recover the heat content from the flue gases of boiler heater.

The system has a rated capacity of 110 mw from a roughly cylindrical salt cavern 300 m deep and 80 m in diameter volume 5 32 million cubic meters.

3 1 is shown in fig.